16mm Windings

2023 was the 100th Anniversery of the introduction of 16mm.

16mm was invented at the time when 35mm was

NITRATE and of course highly inflammable. People shooting home movies and

showing films at home were at risk of having a fire.

16mm was designed to be

made on safety base and made smaller to be more economic, that is cheaper!

16mm was introduced in a paper ‘A New

Sub-standard Film for Amateur Cinematography’ delivered in May 1923 by C E K

Mees Director of Research and Development, Eastman Kodak Company; the paper is

reproduced in the SMPE Transactions Number 16 Pages 252- 258.

16mm was designed as being perforated both

edges. It was considered that you needed perforations on both side to get

a steady picture on the screen. 16mm was not expected to be used

professionally and was called ‘sub-standard’ along with any format that was less

than 35mm in width.

The first stock available to the amateur was

black and white reversal film; film shot in a camera reads through the base so

the first amateur film was effectively a print that read through the base.

35mm prints that have been made

from a negative read through the emulsion.

Other films available to the amateur were

reduction prints made from 35mm originals; printing forwards, which is from the

head, from a 35mm neg onto a 16mm print will produce a print that reads through

the base. The 16mm end of a reduction printer is to all intents and purposes a

camera, in some printers where the printer can be operated in the light it is

actually a camera, so the stock has to be exposed through the emulsion and reads

through the base. This was the SMPTE standard, so prints that read through the

base are called SMPTE prints. They are B winding (see below for explanation)

One of the original suggestions for 35mm

reduction prints was to use double perforated stock and reduction print the

picture and sound simultaneously, this would automatically give a print that was

B winding i.e. the track would be on the left if looking through the base of the

film.

Figures from the SMPE Journal

Volume 19 November

1932

It was decided that it would not be practical

to put the sound track on 16mm in the same place as 35mm, that is inside the

perforations, as it would significantly reduce the picture size and cause

problems in having to modify the gates of projectors because the picture would

be offset. It was decided to remove one set of perforations and have the sound

track on one edge of the film keeping the same picture size, this also enabled

the track width to be increased as it was felt that the reduction in width that

would occur if the track was reduced in the same ratio as the picture would give

inferior sound quality.

When 16mm negative came into use used and a

contact print made for viewing, the print would have the same geometry as a 35mm

print; that is it would read through the emulsion. These became known as DIN

prints. DIN is the German standards institution. They are A winding prints.

(see below for explanation)

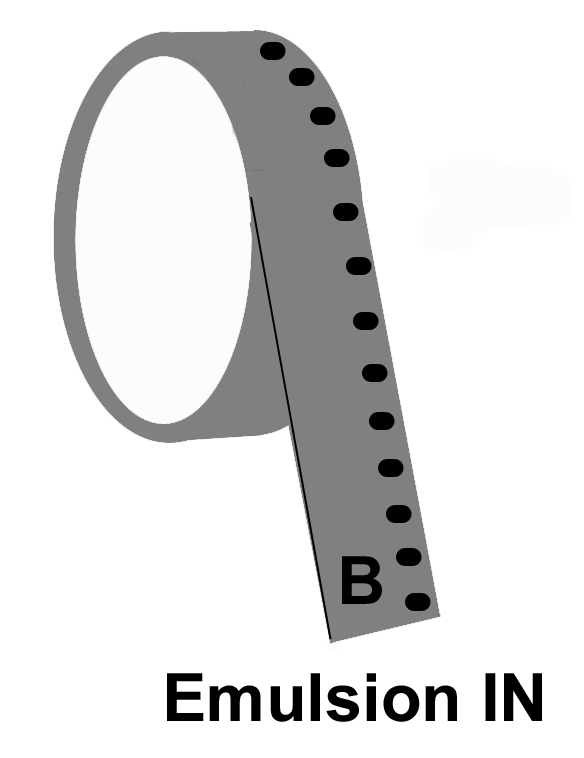

There are two options for single perforated

film; you can have the perforations on the left or the right. In order to be

precise, the windings were designated A and B winding and the winding was

determined when the film was base out, emulsion in.

A Winding Film

Stock B Winding Film Stock

When you purchase 16mm film stock from a

manufacturer you have to specify A, B or double perforated.

Camera original can be double perforated or B

winding, both reading through the base; contact prints made from camera

originals read through the emulsion and can be double perforated or A winding.

Cutting copies are usually made on double perforated print stock so that they

can be run on an editing machine without worrying which side the perfs are on

for viewing.

A double perforated print made from a camera

original can be viewed four ways:

A single perforated print made from a camera

original can only be viewed two ways although it can be printed 4 ways:

If it is printed on to A winding stock from the

head:

The vast majority of 16mm contact printing

machines take A winding print stock and B winding originals because the film has

to be emulsion to emulsion. So if you make a print from a B winding original

negative you will get an A winding print that reads through the emulsion and is

described as a DIN print.

A

reversal original (Colour or Black and White) from the camera will be B winding

or double perforated and read through the base and is described as a SMPTE

print.

Making a negative from it, it will be A winding

if it is contact printed, and will read through the emulsion. If you now make a

contact print from that negative it will be B winding and read through the base

and will be an SMPTE print.

If you have a roll of A winding film stock and

you rewind it, it will become B winding. Because the printer only takes A

winding stock, if you want to print an A winding negative you have to rewind it

and print it from the end, effectively making it B winding and then printing it

onto A winding stock which after processing has to be rewound to make a B

winding SMPTE print.

The sound track has to be on the right side so

sound negatives can be A or B winding: it is vital that you have the correct

winding sound negative to go with your picture negative, if you have a camera

original it will be B winding and require a B winding sound negative and will be

printed from the head. An A winding negative will require an A winding sound

negative and will be printed from the end.

If you make a double perforated print from

either an A winding or B winding negative it does not matter which way you print

the negative as you will be able to project it correctly. However if you print

a double perforated negative that reads through the base from the end onto A

winding stock you will produce a print that cannot be projected correctly. It

will either be upside down or reading back to front. The same would apply if a

double perforated negative reading through the emulsion was printed from the

head.

It is possible to print an A winding negative

from the head if you print it base to emulsion, known as ‘flopping’ the

negative, however there will be a loss of quality and is not recommended.

This could be done if you had a small section

of A winding negative, perhaps made from a reversal original, that had to be cut

into a B winding negative. The correct option would be to make an optical

internegative that was the correct geometry but it would be more expensive.

If you optically print an original you can make

either geometry so you can make a DIN or SMPTE print from a B or an A winding

original.

One exception to printing machines that usually

only take A winding stocks are panel printers which are designed to make bulk

prints. The printer will run forwards and backwards and will take A and B

winding print stock. So with a B winding original negative you would print it

forwards on to A winding stock and then backwards onto B winding stock which

would produce multiple prints without the chore of constantly rewinding the

negative and they would all be of the same geometry, in this case all A winding.

Specifying prints or negatives A or B winding

cannot be confused unlike the use of the terms SMPTE and DIN. Strictly speaking

the terms SMPTE and DIN can only be applied to prints.

There is no agreed standard for naming

negatives and some organisations would call a negative that reads through the

base a SMPTE negative because it reads the same way as a SMPTE print; others

would call it a DIN negative because it makes a DIN print when contact printed.

As was mentioned earlier when you order a sound

negative you have to order the same winding sound negative as the picture

negative. If the picture negative is B winding then the sound negative is B

winding. There can be no confusion. If the negative is identified as SMPTE

there is the confusion discussed above.