Mechanical Defects

Damages to Perforations

The film is driven through most machinery by means of the perforations that also hold the film stationary in a precise position in a camera or projector gate. Many modern processing machines do not use sprocket drive at all, and increasingly telecine and other devices use capstan drive and do not rely on the perforation for drive but only for synchronising. However, this is a recent development and in the past the strain on the film perforations was continuous from every form of transport system. The edges of perforations first burr, then are bent, distorted, and ultimately tear. Burrs and minor damage may cause film to be transported unsteadily and the image to jump or vibrate. Tears can be quite slight, just a millimetre or so along the length of the film path from the corner or the centre of the leading edge and are caused by a single violent stress during drive. These tears, sometimes called split perforations or "crowsfeet" (photos?), often have no effect on the image steadiness but are a potential weakness of the film that could result in a further serious tear in the future. Tears that are more drastic can occur where entire sections of perforations are pulled entirely away.

Repairs to perforations

If the damaged perforations are well repaired, the film will run through a

printer without any problems and maintain a stable image. Further passes of

minor split perforations through a printer or projector may transform these

tears into breaks. Considerable experience is needed to evaluate whether repair

is worthwhile. It is usual to repair as little as possible - just sufficient to

enable the film to be printed.

Some modern printers do not require perforations on both sides of the film in order to transport film steadily, and some printers notably the Sigma and the BHP Modular, and the Rank Cintel telecine, are reported not to need perforations at all for short lengths provided there are no distorted turned up edges. This reduces considerably the effort needed to prepare a damaged film for printing,

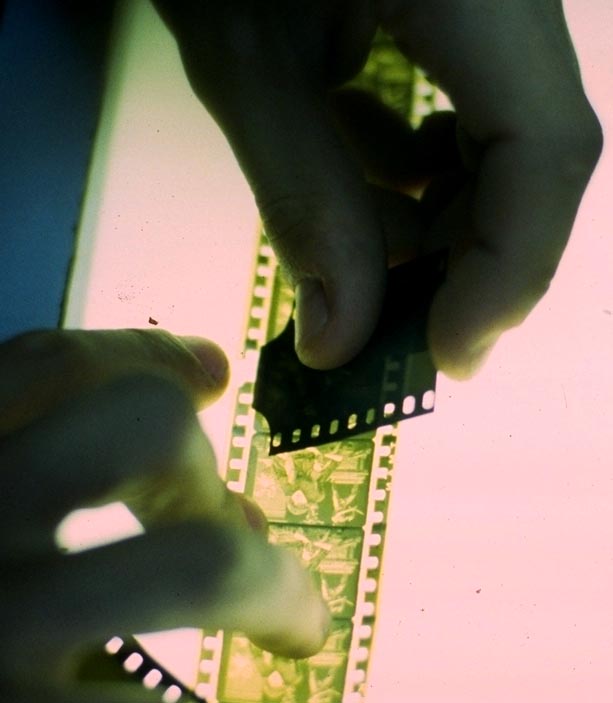

An operator repairing

some perforations using clear, transparent perforated tape. The perf tape, not

being shrunk, can only be applied to a limited length of film.

An operator repairing

some perforations using clear, transparent perforated tape. The perf tape, not

being shrunk, can only be applied to a limited length of film.

|

A piece of film with some repaired perforations. |

|

Tears in the film

Major tears can rip film in half or into many pieces. All tears are repairable with patience, skill, and the right materials if no film is missing. However, whether a tear is worth repairing must be dependant on the value of the image and the quality of the resultant mend as all tears will show as images to some extent.

|

A tear as it appears before repairing |

|

|

Repairing splices

Old splices need to be checked before printing in order to be certain that they will not break on the printer. Telecine machines with capstan drive are less critical, but so much damage can be done to film by a break on a machine that any doubtful splices must be redone. An old join can be tested by a twisting action of the film; if it parts or starts to part, it would have been unsafe on a printer. Sometimes every splice must be remade!

Generally an old insecure splice can be peeled apart, the overlaps re-scraped and re-cemented.

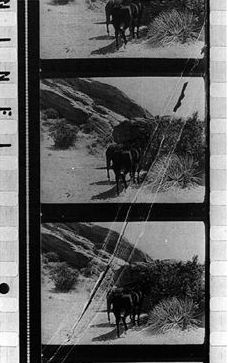

A very

bad splice. Note the different shape and dimension of perforations in the two

films. It is a major problem to repair old splices in such in a way that the

repaired splice will not produce any unsteadiness when printed.

A very

bad splice. Note the different shape and dimension of perforations in the two

films. It is a major problem to repair old splices in such in a way that the

repaired splice will not produce any unsteadiness when printed.

In this case, the

tear has been repaired by applying clear tape.

In this case, the

tear has been repaired by applying clear tape.