TOTAL IMMERSION OR AQUARIUM GATES PRINTING

In this system the printing head with the original film [in the case of an optical printer] or the two films [in the case of a rotary contact printer] is completely immersed in an aquarium containing the re-circulating liquid. Generally, the printing head is placed horizontally, so that the film path is side-to-side, rather than top to bottom as in most dry printers.

The Debrie TAI is an example of an optical printer using this system and BHP, Hollywood Film, Peterson, and Debrie all make total immersion gate rotary contact printers. After printing, the original film passes through a drying chamber or air channel (see figure on pre-wet printing) to remove dry the film before it is wound on to the take-up spool.

All of the liquids used for wet printing are toxic, therefore a good and sufficient exhausting and ventilation system should be provided. As the evaporation fumes of these liquids are heavier than air, there should be an exhausting system on floor level. Perchlorethylene is today almost the only wet gate liquid in use.

|

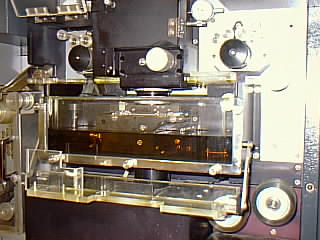

The immersion tank of the Debrie TAI optical printer. Note the level of the liquid in the "stand-by" position. Transport sprockets are placed outside the "aquarium". Note also that a couple of PTR rollers are placed before the "aquarium", to ensure maximum cleanliness of the film. |